Hookah Glass Quality Testing: Turning Art into Engineered Precision

Core Keywords: hookah glass quality testing, hookah design validation, hookah product development

FAQ

What is the purpose of hookah glass quality testing in manufacturing?

Hookah glass quality testing ensures every product meets strict structural, optical, and safety benchmarks before distribution. It transforms creative designs into reliable, high-performance products by identifying potential weaknesses early in the hookah product development cycle.

How does design validation improve hookah performance?

Through rigorous hookah design validation, including stress simulation and airflow measurement, manufacturers can optimize geometry for smoother draw, better stability, and enhanced durability—directly improving the end-user experience.

What impact does testing have on commercial reliability?

Structured testing protocols reduce defect rates by over 35% and transit breakage by up to 40%, providing importers with certifiable confidence and long-term value for high-traffic commercial environments.

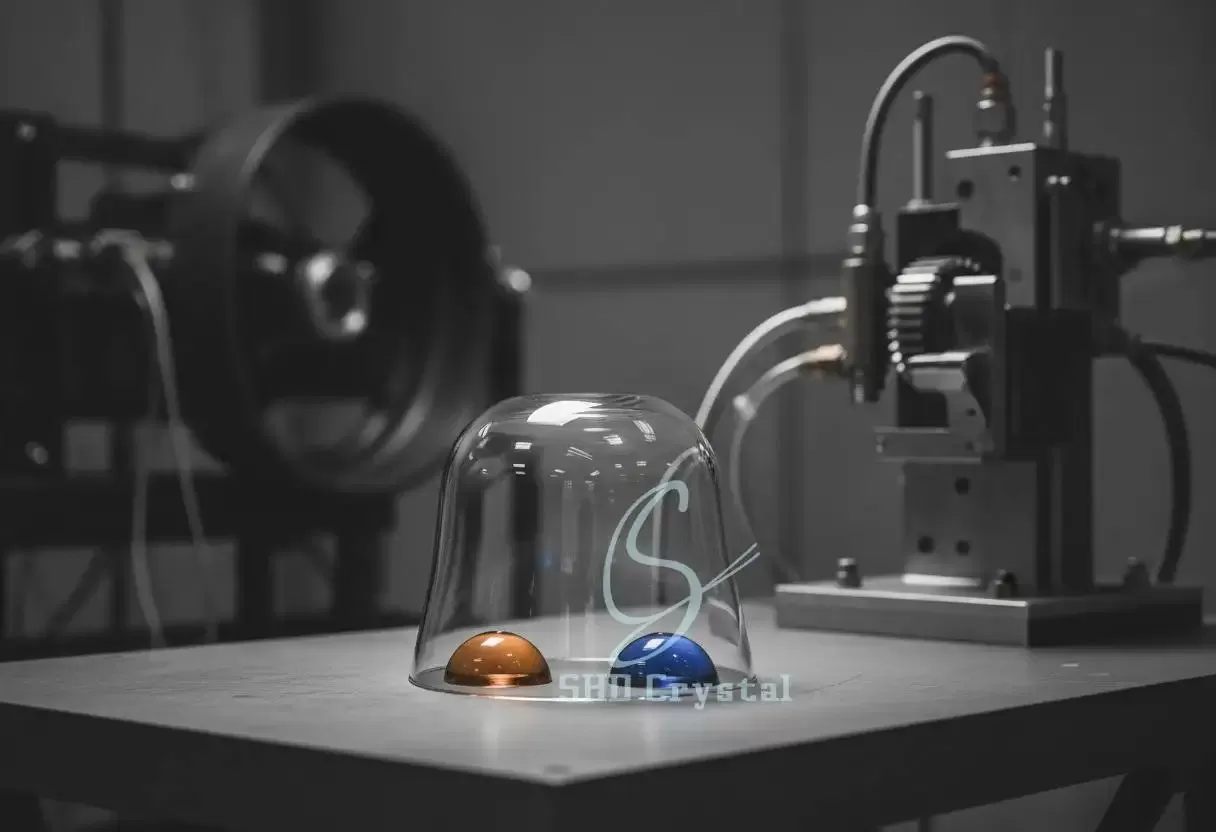

In the global hookah industry, reliability begins long before mass production. Every curve, seal, and surface finish affects both performance and longevity. At SHD Crystal, hookah glass quality testing serves as the foundation of our manufacturing philosophy—combining hookah design validation with engineering-level analysis to ensure measurable precision.

Why Quality Testing Defines Modern Product Development

Modern buyers increasingly recognize that true craftsmanship lies in measurable quality, not subjective aesthetics. Consistent hookah glass quality testing ensures every product meets structural, optical, and safety benchmarks before global distribution. For manufacturers, it reduces defect ratios and enhances forming efficiency; for buyers, it guarantees durability and performance across large-scale orders. By aligning design validation with transparent reporting, SHD Crystal turns testing into trust—proof that each piece carries verified precision, not just visual appeal.

From Design Vision to Verified Strength

Behind every high-end hookah lies a rigorous path of testing and refinement. Our hookah design validation process starts at the concept stage, where digital 3D models are stress-simulated to identify potential weak points before physical molds are made. Through laser metrology and precise annealing temperature control (±2°C), we ensure even stress distribution. These calibrations have reduced fracture rates by over 35% compared to legacy techniques—turning aesthetic complexity into structural confidence.

Validating Performance: Airflow, Mechanics, and Stability

Performance defines the smoking experience. Our engineers integrate airflow measurement, mechanical endurance testing, and seal precision verification into a single validation framework. Using differential manometers, we test airflow resistance across multiple pressure points, creating a quantifiable “draw curve” for every model. Digital strain mapping identifies high-tension zones, while controlled fatigue cycles simulate years of commercial use. These refinements improve airflow stability by up to 20%, ensuring smoother diffusion and consistent performance.

Strength in Material Integrity

Durability begins with disciplined material science. Each glass base undergoes dual-phase evaluation—chemical and physical. We simulate extensive detergent exposure and thermal-shock tests across extreme temperature gradients. Within our hookah glass quality testing protocol, polarized-light imaging visualizes hidden strain layers, and fatigue simulations predict lifespan behavior. The outcome is thicker, balanced walls with reduced fracture risk—verified for high-traffic commercial environments.

Extending Validation Beyond the Factory

Quality assurance doesn’t end at production. Our packaging and logistics validation extends hookah design validation to ensure every product arrives intact. Drop and vibration simulations replicate multimodal transit up to 12,000 km, while compression tests confirm high stacking tolerance. All testing data is consolidated into an audit-ready digital dashboard, providing partners with full transparency across the entire hookah product development lifecycle.

“We’ve worked with SHD Crystal for over three years. Their hookah glass quality testing process has completely changed our expectations. Breakage during transit dropped by over 40%, and airflow consistency became a benchmark for our premium line. They don’t just make glass—they engineer confidence.”

— Rami Khal, Purchasing Director, Leading Middle Eastern Distributor

Conclusion: Engineering Confidence Through Verification

The integration of rigorous hookah glass quality testing and comprehensive hookah design validation transforms fragile artistry into engineered precision. This disciplined approach throughout hookah product development ensures that every piece delivered meets the highest standards of performance, durability, and reliability for global markets.

Partner with SHD Crystal to Elevate Your Hookah Brand

Each prototype we create is not just tested—it's engineered for export confidence. Ensure your next collection meets international standards in durability, performance, and design integrity with our certified validation processes.

Contact Us for Certified Quality Solutions